ROTALIGN touch – The Original

If you set out to be original, prepare to be copied. 'Never judge a book by its cover' rings true as what you see on outside is often quite different on the inside.

The ROTALIGN touch truly is unique. Let's find out how the leading laser shaft alignment system delivers the best measurement accuracy while offering the most innovative features that save you time and effort.

Watch and find out: How can you benefit from our single-laser technology?

Why single laser technology?

Setting up one laser beam to hit the opposite sensor is much faster than setting up two. In the field, this saves you a great amount of time setting up the measurement.

The distance between two machines or length of the spacer shaft never affects the measurement. With a single laser, measurements are based on a fixed distance, which is the distance between the two detectors inside the sensor. For the user, this means that it does not matter whether the distance is very short or very long; a single-laser system always delivers the same accuracy.

It is always possible to measure no matter the initial angular misalignment. Thanks to the extension of the detector area, there is no need for a pre-alignment, unlike with dual-laser systems. Therefore, with a single laser, you can document the initial alignment condition as found, as well as the condition as left.

ROTALIGN touch: A Revolutionary in Alignment

The ROTALIGN touch is the most powerful laser shaft alignment platform on the market.

Whether you’re looking for an effective and reliable tool for your daily use or powerful tool that can measure up to even the most demanding tasks, be ready for any job that comes your way.

FeaturesSuccess Story

Gas turbine alignment in less than an hour

The standard functions of the ROTALIGN touch made it ideally suited to perform the alignment of the gas turbines

to a steady bearing pedestal despite the large angular thermal growth offsets.

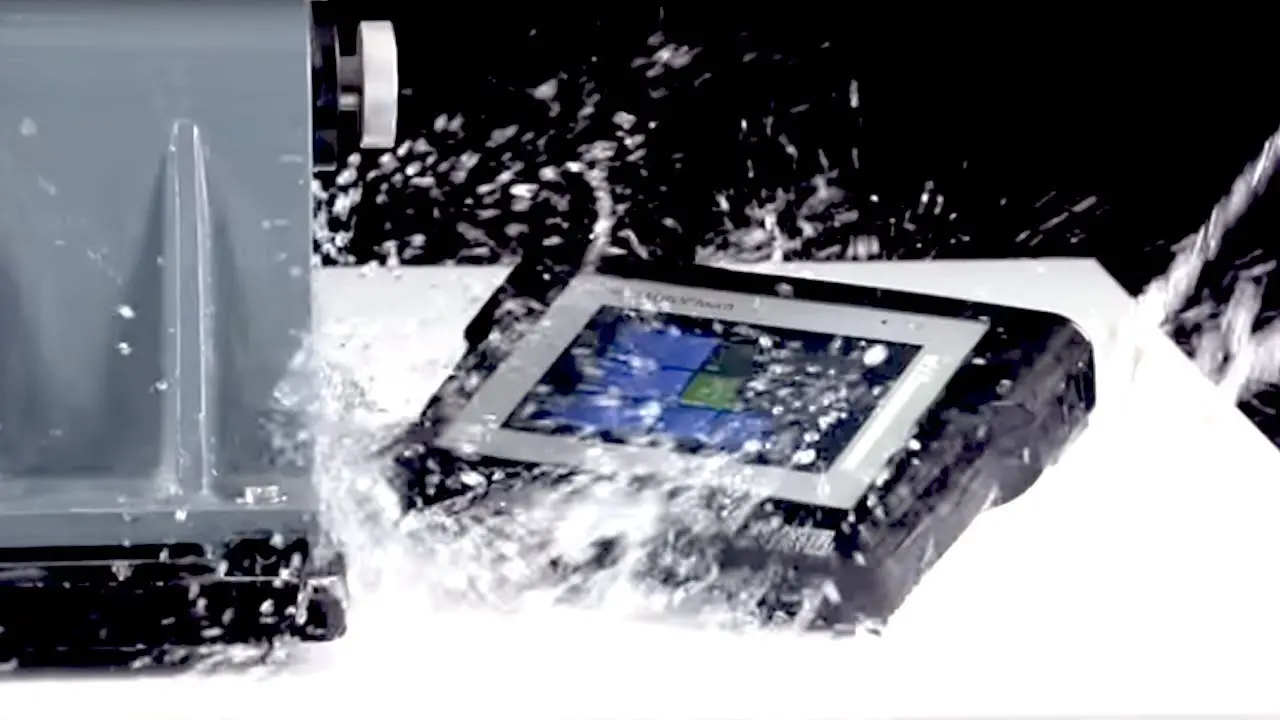

A Tool Designed for The Most Rugged Environment

Tests have been taken to evaluate the ROTALIGN touch's resistance to: water, dust, drops, impacts, and cold temperatures.

ROTALIGN touch: the go-to tool for the harshest working conditions.

Free product demoA Feature for Every Job

Maintenance today for a more reliable tomorrow